ABOUT HEXAGON

- From microns to mars

A global leader in digital‑reality solutions, Hexagon combines sensors, software and autonomous technologies to turn data into higher efficiency, productivity, quality and safety across industrial, manufacturing, infrastructure, public‑sector and mobility applications. These technologies are shaping production‑ and people‑related ecosystems to become increasingly connected and autonomous—ensuring a scalable, sustainable future.

Hexagon’s Manufacturing Intelligence division provides solutions that use data from design and engineering, production and metrology to make manufacturing smarter. By bridging the physical and digital worlds with real‑time, actionable insight, these metrology solutions close the gap between design intent and real‑world operation, empowering quality teams to drive innovation across the entire product lifecycle.

When it has to be right, it has to be Hexagon. – watch video.

- Hexagon’s Manufacturing Technologies Are Used In:

- 95% of All Automobiles Worldwide

- 90% of All Airplanes Worldwide

- 80% of All Orthopedic Implants Worldwide

- 75% of All Smartphones Worldwide

- Hexagon by the Numbers:

- Apprximately 24,500 Employees Across 50 Countries

- 100,000+ Manufacturers Worldwide Using Hexagon Products

- 200+ Years of Hexagon Manufacturing Intelligence History

- 5,500+ Active Patents

Hexagon Technology in Action

1

Driving Precision with Orcale Red Bull Racing

Watch the world’s best Formula 1 team achieve 50% fewer faults in two years with Hexagon’s technologies. – learn more.

2

Quality: Bringing Fusion Energy to Life (ITER)

Learn how ITER is laying the foundation for a clean energy future in the South of France, powered by precision metrology solutions. – learn more.

3

Shaping Discovery: How CERN Explores the Universe’s Mysteries

Discover how the world’s largest physics research organisation uses Hexagon’s technology to measure within 1/100th of a hair. – learn more.

4

Portable Measuring Arm High-Quality Inspection for Audi E-Tron

Explore how an Absolute Arm with laser scanner allows Audi Brussels to perform innenmeisterbock inspection more efficiently, reliably and quickly than ever. – learn more.

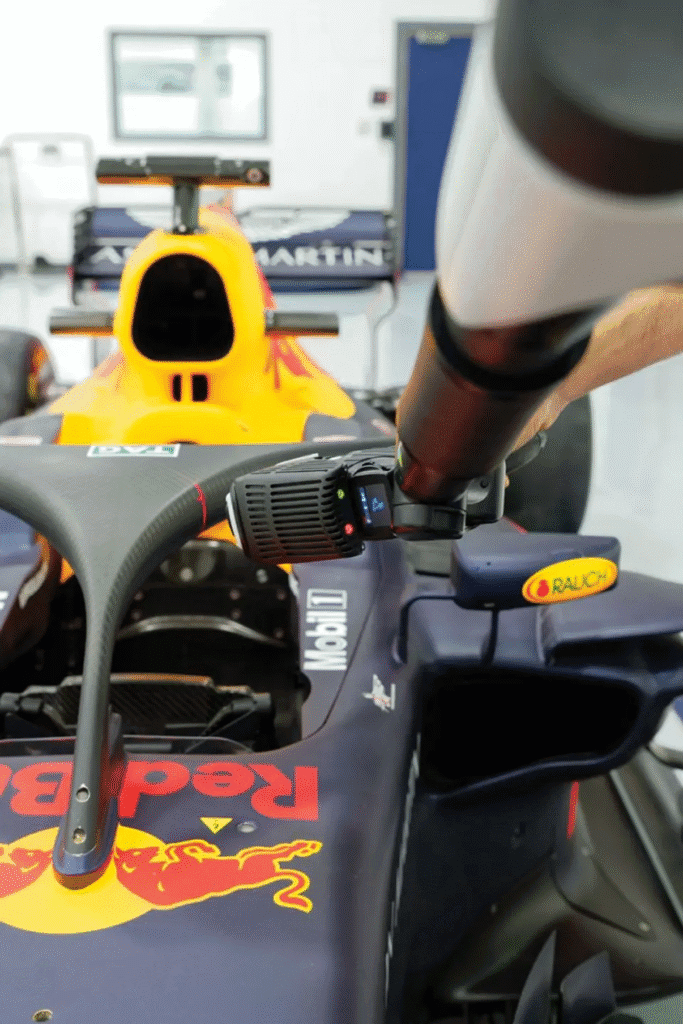

Laser Scanning for Quality at Red Bull Racing

Watch how Red Bull Racing uses their Absolute Arm 7-Axis and Absolute Tracker AT960 with their Absolute Scanner AS1 to ensure quality.

Have Questions?

Feel Free to Contact Us!

We offer demos, application advice, quotations, installation, training, and service across Indonesia. Share your application, tolerances, and budget—we’ll propose the most effective solution.