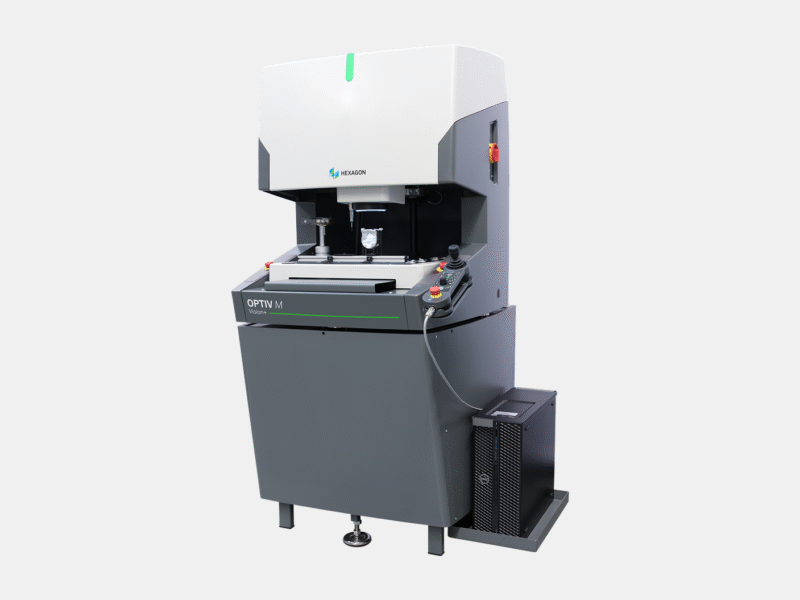

VISIUS

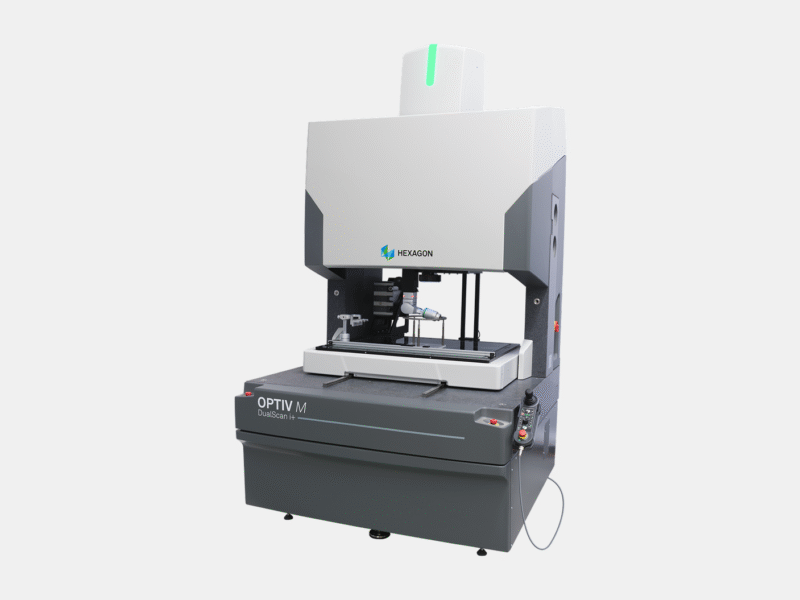

VISIUS offers fast vision measurement, ease of use and ISO 10360 compliant measurement accuracy at an attractive price point. VISIUS forms the new entry into Hexagon’s portfolio of optical coordinate measuring machines and brings automated high-speed 2D measurement to your quality control process.

The solution combines fast non-contact vision measuring and reliable accuracy with easy-to-use software in a versatile measuring system at low costs. VISIUS is the ideal solution for price-sensitive customers seeking to cover basic dimensional measuring applications in environments where efficiency is a key productivity driver.

Measure at the Speed of Production

- With VISIUS, you’ll eliminate time-consuming manual inspections and increase your measurement throughput.

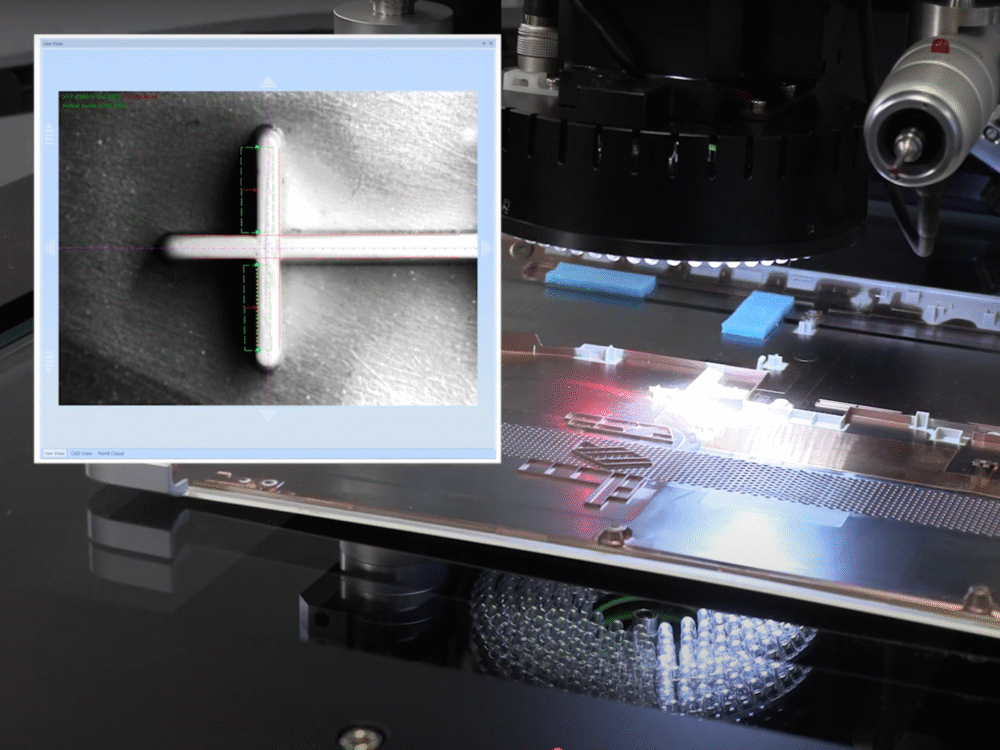

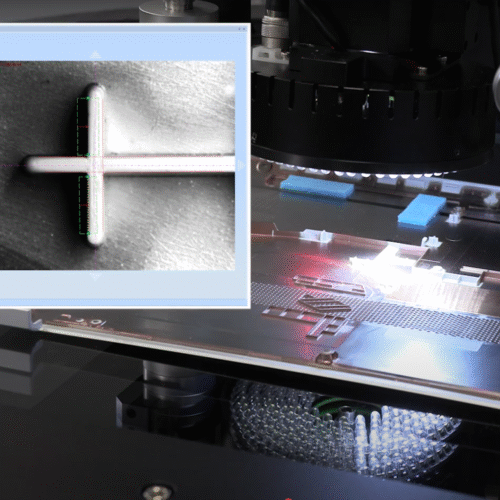

- The vision sensor on VISIUS instantly captures a vast amount of measuring points in the camera’s field of view. Slash cycle times by performing multiple inspections from a single acquired image.

- Benefit from a high level of measurement automation. Run VISIUS unattended and execute measurement cycles with no need for manual interventions.

Help Operators Get Productive More Quickly

- VISIUS is paired with the easy-to-use metrology software Metus.

The software flattens the learning curve for operators of all skill levels and allows them to efficiently perform robust measurements with minimal training. - Metus removes complexity from measurements. Guided workflows minimise operator variability and cut the time needed to setup and execute “first-time-right” measurements.

- VISIUS features an overview camera to enable fast point-and-click part navigation and programming within a live Navigation View right in Metus without having to use the joystick.

Make Trusted Measurement Results Your Commitment to Quality

- VISIUS is a rock-solid optical CMM. The system will remain steady even in the face of harsh ambient conditions, eliminating variabilities in your quality control processes.

- VISIUS offers ISO 10360 standard-compliant accuracy, ensuring traceability and reliability of measurement results. You’ll instil greater trust among your customers by preventing misjudgments of part conformity and related costs for rejects or rework.

- Highly reliable measurement results allow optimal exploitation of specified manufacturing tolerances, which opens cost-saving potentials in the production.

Basic Configuration: VISIUS comes in a simple all-in-one configuration and in three machine sizes. The basic version comprises, as standard, the non-contact vision sensor as the primary measuring sensor and an overview camera for easy part navigation and visualisation. Also included in the package is the easy-to-use metrology software Metus. VISIUS is calibrated to ISO 10360 standards.

Options for Multisensor Flexibility: VISIUS offers multisensor integration for the touch trigger probe and the chromatic white light sensor (CWS). This enables more complete, single-cycle measurements from only one machine, with less part handling, increased measurement throughput and at lower cost.