MARVELSCAN

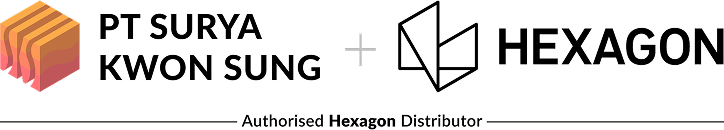

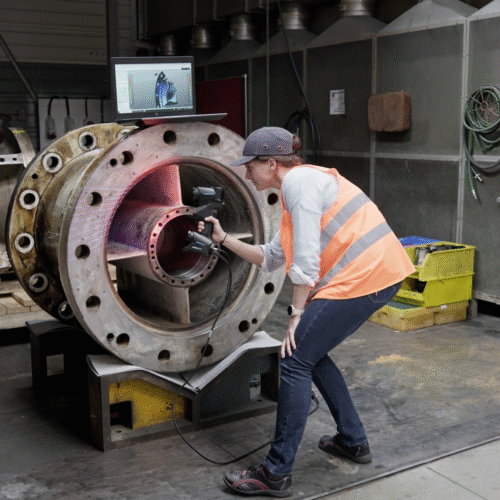

Photogrammetry-augmented handheld 3D scanner for wireless and targetless measurement anywhere. Scan where needed without restrictions – MARVELSCAN can reach into hidden areas and see inside deep cavities, with no line-of-sight limitations. A lightweight handheld 3D scanner makes it straightforward to take the inspection process to the measurement object instead of bringing the part to the quality room. Break free from cables and referencing hardware with complete wireless connectivity.

High-quality 3D scanning without part fixturing – even a moving part is no barrier to perfect measurement results thanks to Dynamic Scanning functionality. The photogrammetry-powered target-free functionality of the MARVELSCAN makes it ideal for the scanning of large or delicate parts as well as repetitive scanning processes.

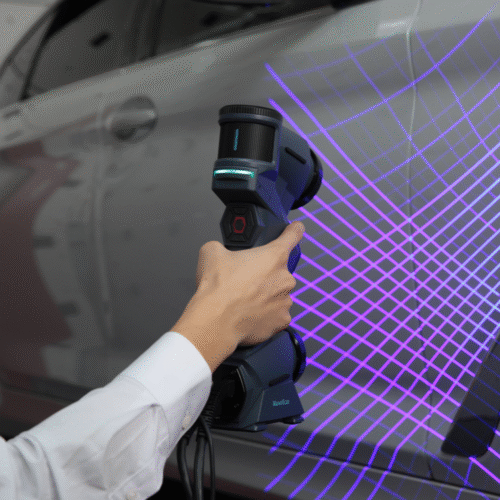

Change scanning modes directly from the handheld 3D scanner happens at the touch of your fingertip, with options for larger-scale measurements, higher-definition feature inspection, hard-to-reach areas and multiple holes and slots. Data collected by the MARVELSCAN with different 3D scanning modes is seamlessly combined within the same point cloud/mesh.

Freedom of Movement: Reach into hidden areas and cavities, get the right inspection angle without line-of-sight restrictions, scan at height, at distance, on the shop floor or in the field.

Lightweight Ergonomic Design: Fits perfectly in the hand and light enough to take anywhere and scan for hours.

Wireless Scanning Module: Set yourself free from movement limiting cables and referencing hardware with full wireless functionality.

Truly Handheld Scanning: Take the part in your hand and the scanner in the other for a very quick scan process that requires no complex part fixturing thanks to Dynamic Scanning.

Unstable Measurement: Even challenging environment conditions with extreme noise and vibration are no problem for Dynamic Scanning.

Target-Free Scanning: Effortlessly scan without targets on the part using photogrammetry for referencing against a target backdrop, delivering significant time savings in part preparation.

Built-In Photogrammetry: Thanks to the third camera, it can be used as a standalone photogrammetry providing an all-in-one solution, scanning utilizing photogrammetry technology to enhance scanning accuracy for bigger part size.

3 Scan Modes: Standard, Fine and Line scanning modes let you tailor your scanner performance to the application at hand, for greater efficiency or resolution as needed.

Multi-Size Target Recognition: Maximise efficiency by using different target sizes (3/6/12/16mm) for different applications during the scanning process.

Change Modes On-The-Fly: Switch between scanning modes during measurement, directly from the handset, allowing you to fine-tune performance not just to the application but individual sections of the application.

Combine Scanning Mode Results: Data collected with different scanning modes is seamlessly combined within the same point-cloud/mesh for ease of analysis and reporting.

Hole Flash Capture Technology: Rapid simultaneous inspection of multiple circular and slotted features speeds up the workflow for a key industrial inspection challenge.

Instant Visual Feedback: Know you’re scanning correctly without returning to the control computer with built-in LED feedback system on the handset.

Large Standoff: Collect data from further away from the part, making it easier to access internal inspection areas such as tooling cavities, as well enabling automation system integration with lower collision risk.

VDI/VDE Certification: Results are certified in line with the VDI/VDE 2634 to assure reliability and comparability of measurement.

Automation Ready: The MARVELSCAN is ready for straightforward third-party integration within automated inspection systems.