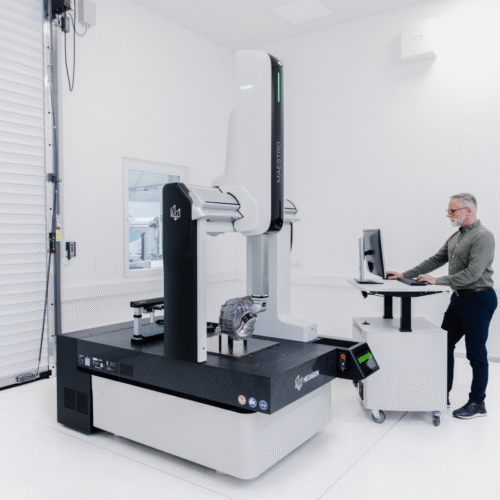

MAESTRO

MAESTRO is Hexagon’s all-digital, fully connected CMM system – purpose-built for modern manufacturing. Designed from the ground up, MAESTRO combines high-performance hardware and intelligent software to deliver industry-leading speed, simplified operation, seamless connectivity and long-term adaptability.

With MAESTRO, unparalleled speed is achieved through a combination of synchronised movement and swift sensor changes during operation. The machine moves fluidly and extremely fast, without interruption. Wrist axis and machine axis operate in sync. Even probe changeovers are much faster with MAESTRO. Improvements of up to 50% are possible. It’s fast and easy to set up MAESTRO, create and run programs with Metrology Mentor and PC-DMIS, and interpret the data with Metrology Reporting. Hexagon’s connected hardware and software are designed to work together to provide the fastest and easiest CMM experience anywhere.

The core principle behind all MAESTRO hardware and software is simplicity of operation. The machine’s clear display gives detailed information – including warnings, status, and operator instruction – so decisions can be made quickly and efficiently. Metrology Mentor software simplifies workflows by removing the need for programming, enabling any user to apply the most appropriate measurement strategy to any task, and deliver accurate and reliable metrology results. And thanks to rapid and easy wrist replacement, downtime is minimised so MAESTRO can get back to work fast, with less service intervention.

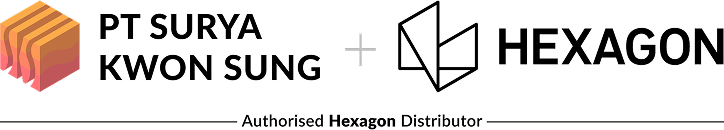

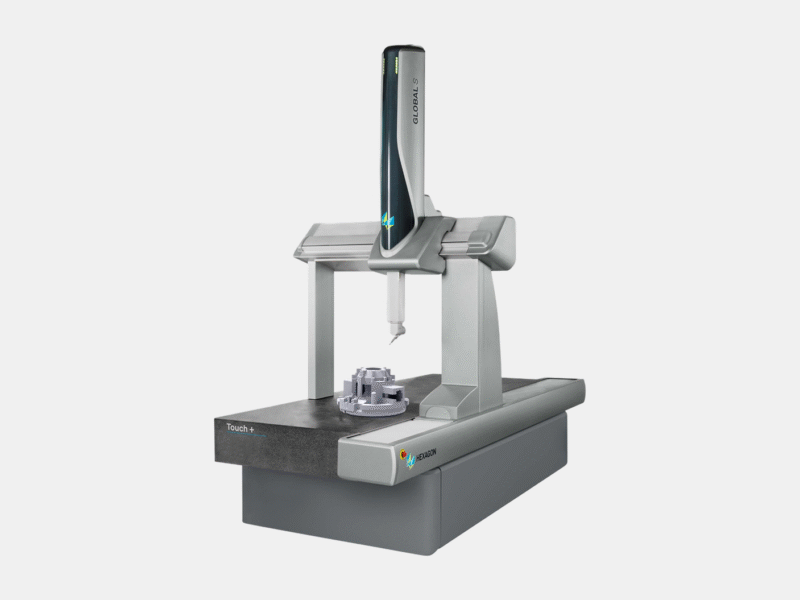

MAESTRO Touch+: General-purpose measurements of size features with highly repeatable touch trigger probing.

- Digital touch trigger probe DTT

- Metrology software PC-DMIS CAD

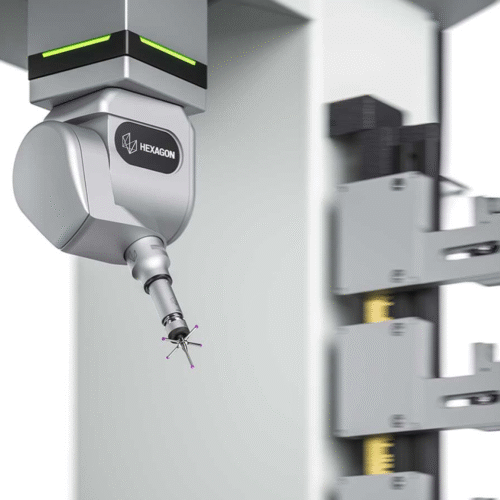

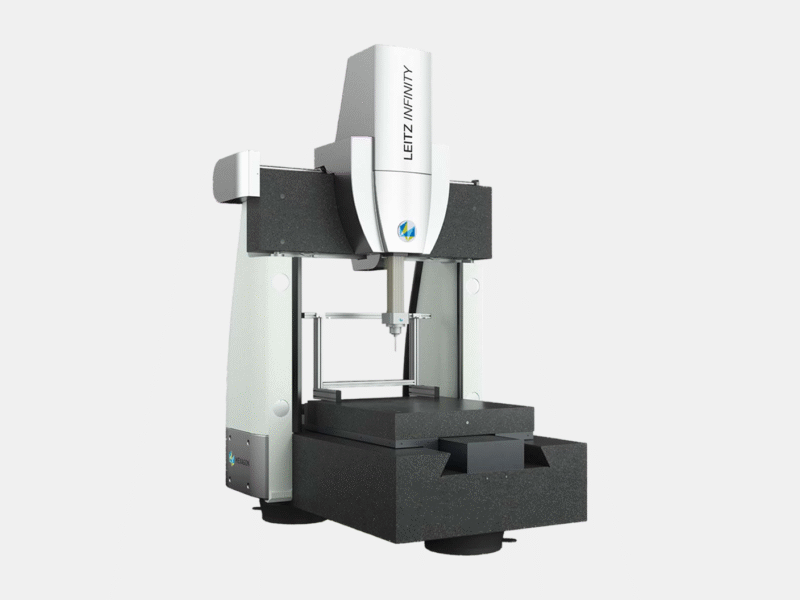

MAESTRO Scan+: General-purpose measurements of size and form features with high performance tactile scanning.

- Digital scanning probe DST 200

- Metrology software PC-DMIS CAD++

- Scan Pilot for improved scanning performance

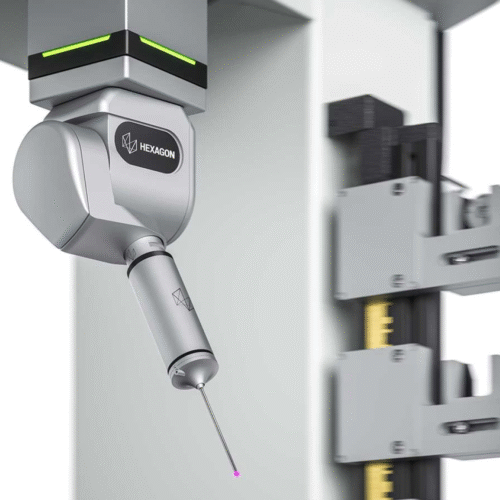

MAESTRO Speed: High throughput measurements of complete part surfaces with high measuring point density.

- Digital laser scanner DSL 100

- Metrology software PC-DMIS CAD++

- Scan Pilot for improved scanning performance

- Digital changer rack DR including modules for DSL 100

Digital Sensors: The digital wrist DW 2.5 enables maximum measurement flexibility through optimal positioning of the sensor towards the workpiece. This wrist has an infinite rotation 360° B-axis and indexes in 2.5° increments to achieve 12 240 unique positions.

The digital touch trigger probe DTT is a 6-way probe for highly repeatable 3D point measurement. The modular design enables operators to quickly change modules and styli configurations without recalibrating.

The digital scanning probe DST 200 allows fast, accurate contour and form measurements with the best-suited orientation. Carries styli up to 200 mm in length (axial direction) and 225 wide (lateral directions). The scanning probe has additional styli clampings, so operators can change styli configurations fast, without recalibrating.

The digital laser scanner DSL 100 enables rapid, highly accurate non-contact capturing of complex part surfaces with high measuring point density. Unique usability features allow fast and easy programming and handling.

Digital Changer Rack: The only rack you need, this allows for automated exchange of sensors and styli configurations during the measuring cycle without recalibration. Easy to install and calibrate, it provides the highest modularity – e.g., by equipping it with up to three layers, in different widths, and available with various modular and easy-to-install sensor and styli ports. The digital changer rack fully integrates with the digital twin to monitor the position and occupancy status of each installed port, in real time, to reduce programming and measuring cycle times. The known occupancy of sensor stations reduces the risk of sensor collisions.

Camera System Smart Machine Eye (SME): An embedded camera system for enhanced remote trouble shooting, root cause analysis, user guidance and technical support. Can be deactivated by use of a mechanical blind.

Status LEDs and Display: The MAESTRO CMM features Status LEDs and a display for comprehensive status monitoring. Status LEDs, located on the Z-tower and sensor interface, allow users to view the machine’s status from a distance. They indicate various states such as machine operation, warning, alarm, and standby or waiting mode.The display provides more detailed information about the machine’s condition. It shows whether the machine is ready to operate, provides detailed warnings and alarms, and offers specific details when the machine is waiting for an operator’s action.

Sensor Unit and Interface: Located on the Z-tower, the sensor unit supports current and future technologies with streamlined cabling for easy upgrades. The sensor interface connects to the Z-quill and CMM frame, featuring LEDs for immediate feedback, and facilitating easy replacement of probe heads.

Integrated Controller: Integrated into the machine frame, this controller eliminates the need for an extra cabinet and requires just one cable to the operator’s desk, allowing the operator PC to be the only device there. The controller supports software updates without hardware changes and is ready for automation.